The issues:

- A really, really (I mean really) old hand-held technology that was failing daily

- Over $300k/day in outstanding errors with our customers

- Inventory shrink in the millions due to system issues

- The list goes on…

Rand McNally was using hand-held technology for its Direct Store Delivery (DSD) operations. It was deployed in the late 80’s to service over 50,000 customer locations throughout the US and Canada.

The developer of this mission critical system was an outside vendor whose only employee who still knew the system was a walking heart attack waiting to happen; we were losing millions in inventory because the system was not recording transactions correctly; the system allowed us to place unauthorized product in our customer locations resulting in fines and refusal to pay our bills. Bottom line, the technology needed to be replaced and replaced quickly.

The mission:

Our new company president asked me to find new technology, develop, test and implement a new system within six months.

The resolution:

Working with our Canadian operation as our test case. We evaluated and selected a Canadian firm, Filbitron, to modify their existing DSD system to meet our needs. We were in the field testing MapTrac within 30 days and fully rolled-out and testing in Canada within 60 days. During rollout testing in Canada, we began system modifications and testing for the US operation. This was a company-wide initiative that involved the entire Information SERVICES, Operations and Supply Chain departments.

During the project, concern was expressed with the accuracy of the system. I brought in an outside auditor, who audited and certified every transaction for completeness, internal controls and accuracy. Faith was restored and the project resumed.

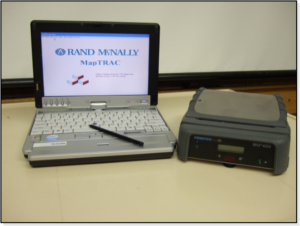

Within 120 days we were rolling out and training the over 200 US DSD representatives. The teams worked tirelessly to make the project a success. The project cost just slightly over $1 million to implement and payback was achieved within the first year of operation. A second generation of the system equipment was successfully rolled out in 2007/2008 (see picture above).

As a result of the new system we:

- Improved DSD in-field productivity by 100%+

- Increased our incremental capacity and revenue by over 20%

- Eliminated in-field errors by 99%

- Reduced our inventory adjustments to less than 1% by the next physical inventory.

We were recognized by our vendor as the fastest implementation in their history.